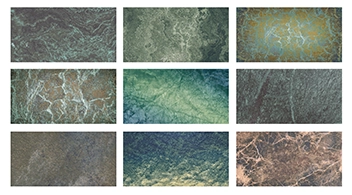

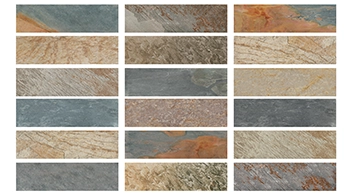

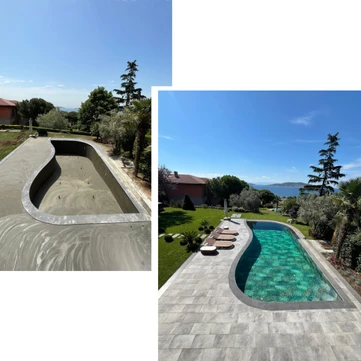

Pool coating refers to the finishing phase carried out after pool construction, in which appropriate materials are selected according to the pool's dimensions, design, and intended use. Various materials such as porcelain, ceramic, glass mosaics, porcelain mosaics, pebble finishes, and natural stones can be preferred. The right material should be selected based on key factors like pool usage frequency, structural design, user profile, and environmental conditions.

How Is Pool Interior Coating Applied?

The process starts with selecting the appropriate material. Once the correct dimensions are determined and the rough construction is complete, the surface must be thoroughly cleaned and prepared for application. Materials with high resistance to water, chemicals, and weather conditions should be prioritized. The coating process generally begins from the pool walls using adhesives compatible with the selected material. After application, a minimum of 12 hours should be allowed for the surface to fully cure.

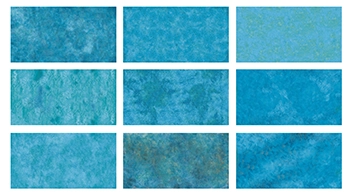

What Is Porcelain Pool Coating?

Porcelain pool coating is one of the most preferred methods due to its durability and sophisticated appearance. Serapool offers a wide range of high-quality porcelain coating materials in various sizes and patterns, tailored to diverse project requirements. Porcelain coatings are widely used in residential pools, thermal facilities, and commercial pool areas. Key porcelain products for pool interiors and surroundings include:

- Porcelain mosaics

- Pool interior porcelain tiles

- Porcelain anti-slip terrace tiles

- Porcelain pool grates

- Porcelain pool channels

- Porcelain stair non-slip pieces

- Porcelain pool coping

Advantages of Porcelain Pool Coating Materials

- Provides watertight performance, extending the pool’s life cycle.

- Offers decorative elegance with rich color and pattern options.

- Increases safety through anti-slip finishes, minimizing the risk of falls and injuries.

- Ensures hygienic use with low water absorption.

- Does not crack or break under extreme weather conditions.

- Exhibits high resistance to impacts and heavy loads.

- Fired at high temperatures for a dense, non-porous structure that prevents bacterial growth.

- Colors and patterns maintain their vibrancy thanks to superior fade resistance.

- Delivers a long-lasting and low-maintenance solution.

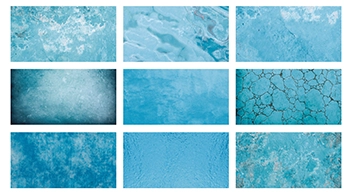

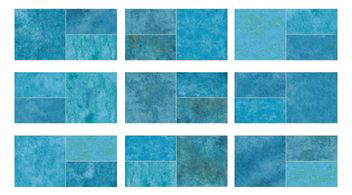

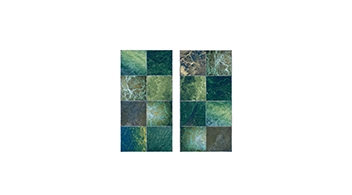

What Is Glass Mosaic Pool Coating?

Glass mosaics are commonly used materials in pool coatings, typically produced in blue tones for a classic look. These mosaics are applied to pool floors and walls using cement-based adhesive. During installation, excess mortar should be wiped off with a damp sponge before drying. Full curing generally takes about 10 hours.

Disadvantages of Glass Mosaic Pool Coating

- High water absorption may lead to cracking or breakage.

- Lack of anti-slip finish can pose safety concerns.

- Improper cleaning results in cloudy water appearance.

- Excessive grout lines can increase installation costs.

- Breakage may lead to sharp edges, posing injury risk.

- Over time, pieces may detach, affecting visual appeal.

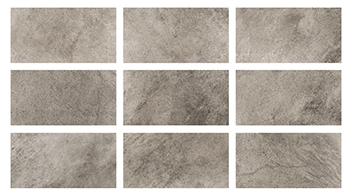

What Is Ceramic Pool Coating?

Ceramic tiles are more vulnerable compared to other materials. They are sensitive to impacts and wear easily in high-traffic areas. Abrasive cleaners and highly acidic products should be avoided, as they may damage the surface.

Disadvantages of Ceramic Pool Coating

- Low-quality ceramic tiles may fade due to UV exposure.

- High water absorption creates hygiene risks.

- Porous structure allows bacterial formation.

- Prone to cracking under extreme temperatures.

- Capillary cracks may form due to water absorption.

- Breakage can pose safety hazards.

- Limited chemical resistance.

- In some cases, costs may exceed those of mosaics.

Key Considerations in Pool Coating Applications

Expertise is essential in the pool coating process. Professionals with proven experience directly influence both craftsmanship quality and the longevity of the pool. All materials used should be first-class in terms of aesthetics and durability. It is also important that selected materials are easy to source in case of future repairs. After coating is complete, the pool should not be filled with water until it is fully ready for use to ensure long-term performance and preserve the coating’s integrity.