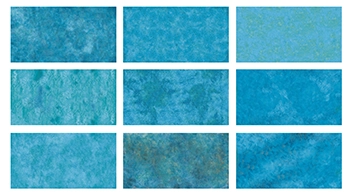

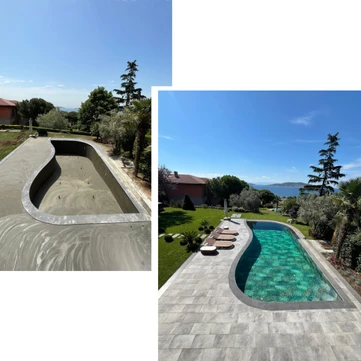

Grouting, the most commonly used material for bonding and securing tiles, is essentially a filling compound. In pool construction, grout is one of the indispensable materials, playing a vital role in enhancing both the durability and overall value of the pool. For this reason, grout must be selected from a reliable, high-quality brand, applied with precision, and properly maintained.

Pool grout is applied to the gaps intentionally left between the installed tiles. Silicone-based grouts are also frequently used in these areas. To prepare the grout, the dry mixture is blended with water to achieve the correct consistency. The grout used for pools should have a thick and flowing texture. Its primary function is to prevent water from seeping beneath the tiles.

How Is Pool Grouting Applied?

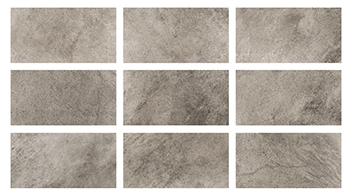

During pool construction, Porcelain Tiles must be placed with 3 mm spacing to ensure effective grouting. Placing the tiles flush against one another prevents proper grout application. Prior to application, the entire surface must be thoroughly cleaned of dust and debris. Grouting should only be done on smooth and clean surfaces, using professional workmanship. It's essential that the adhesive under the tiles has fully cured before applying grout. To protect Porcelain Tiles and avoid staining, it is recommended to use surface protectors before the grouting process.

Key Points to Consider in Pool Grouting

Important factors in pool grouting include:

- If the gap between tiles is too wide, the grout may not adhere properly. Always apply grout suitable for the specified width (as indicated on product packaging).

- The surfaces must be cleaned and cleared of construction residues.

- Waterproofing must be applied beneath the tiles before grouting begins. This is crucial to prevent water leakage and ensure long-term pool performance.

- After completing the grouting, wait at least 30 minutes, then clean the area with a cloth or sponge.

- Ensure that no voids are left between tiles during application.

When Can the Pool Be Used After Grouting?

Pools can typically be used 4 hours after grouting. However, this period may vary depending on the brand and type of grout used on the pool floor and walls. Once the surface is fully dried, the pool can be filled and ready for use.

What Happens If Pool Grouting Is Not Applied?

Without grout, a pool's service life is significantly shortened. Grouting prevents water from seeping through the tile joints, corners, and connection points. Regardless of whether the pool is used seasonally or year-round, grouting is essential for maintaining water insulation. Available in various colors and thicknesses, grouting—when paired with high-quality materials and proper workmanship—can last for many years.

How to Maintain Pool Grout?

The frequency of maintenance depends on the size of the pool. If grout is not maintained, it will eventually deteriorate and become a breeding ground for algae, bacteria, and dirt. The maintenance process involves draining the pool, cleaning damaged or detached grout, thoroughly washing the surface, and applying fresh grout. After allowing it to cure completely, the pool can be safely reused.

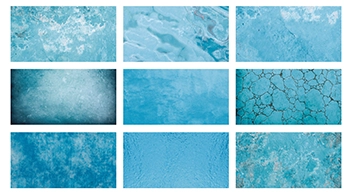

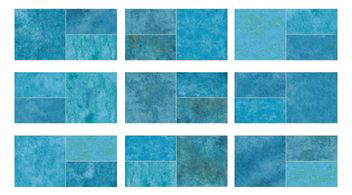

Types of Pool Grout

The most commonly used grout types include:

- Antibacterial Grout (2 mm – 10 mm)

- Epoxy Grout (2 mm – 15 mm)

- Silicone-Based Grout (2 mm – 10 mm)

Should Pool Grouting Be Renewed Annually?

Grouting is inspected during routine annual maintenance. If no damage is detected, replacement is not necessary. However, even minor damage should not be ignored. For the safety and cleanliness of pool water, regular and careful grout maintenance is a must.

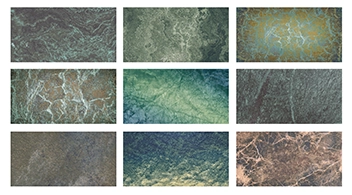

Key Properties of Pool Grout

- Resistant to extreme temperatures: from +50°C to -30°C.

- Provides high-quality water insulation to prevent leakage.

- Offers Chemical Resistance against substances in pool water.

- Flexible in structure.

- Prevents issues like blistering and cracking with regular maintenance.

- Ensures a smooth transition between Pool Tiles on floors and walls.

- Maintains its color when made from quality materials.

The Importance of Pool Grouting

Pool grout plays a crucial role in keeping water contained and preventing leakage. It also contributes to the structural integrity and longevity of the pool. The more robust the materials used during pool construction, the fewer renovation issues arise in the future. Therefore, applying grout after Pool Tiles are laid is essential not only for preventing chemical contamination but also for overall pool performance and user health.