When selecting a pool cladding material, technical features are just as important as visual appeal. Especially for surfaces exposed to continuous use and outdoor conditions—such as pool floors and walls—the structural quality of the material directly affects everything from appearance to long-term safety.

Therefore, choosing the right pool cladding is not just a design preference; it is a technical investment. Understanding the difference between ceramic and porcelain is key to ensuring lasting satisfaction and performance. The “porcelain vs ceramic” question must be answered not only in terms of aesthetics but also in terms of safety and durability.

What Is Ceramic? How Is It Made?

Ceramic is a surface material produced by firing natural clay and mineral-based raw materials at specific temperatures. It is known for its porous structure and water absorption rate ranging from 3% to 7%.

For this reason, it is mostly preferred in interior ceramic tile applications. While ceramics can meet visual expectations, they offer limited durability against harsh environmental conditions. This makes ceramic tiles a less reliable solution for outdoor use over time.

What Is Porcelain?

Porcelain is a much denser and less porous material than ceramic. It is made from purer raw materials and fired at significantly higher temperatures. This process reduces the water absorption rate of porcelain to below 0.5%.

As a result, porcelain tiles offer outstanding resistance to water, chemicals, and frost. This makes porcelain the go-to material for outdoor spaces and surfaces in constant contact with water. The non-porous structure of porcelain also prevents bacterial growth, thus ensuring superior hygiene standards.

Key Differences Between Porcelain and Ceramic

Durability, Water Absorption, and Frost Resistance

Ceramic absorbs water over time, which can weaken its structure and cause cracks in freeze-thaw cycles. In contrast, porcelain’s low water absorption ensures it remains unaffected by such cycles. Its dense body provides superior resistance to breaking and wear.

This is why porcelain is the ideal solution for a safe and long-lasting pool. Its technical advantages make porcelain the preferred material for those seeking durable pool finishes.

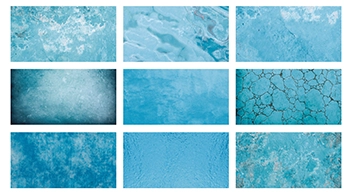

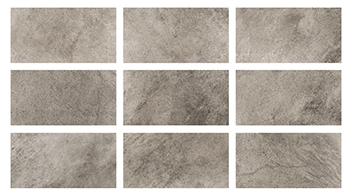

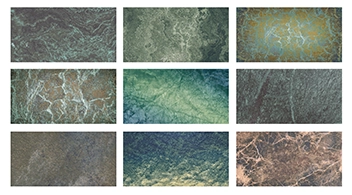

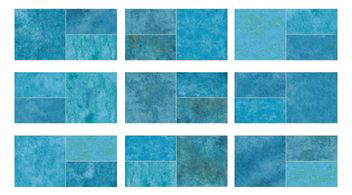

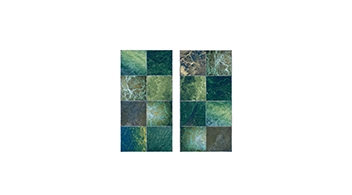

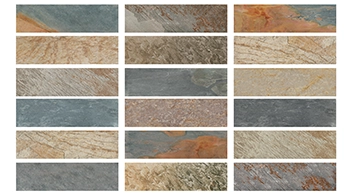

Aesthetic and Surface Qualities: Color, Texture, and Pattern

Visual details are just as crucial as functionality in surface materials. Thanks to high-temperature firing technology, porcelain tiles retain their color and texture for years. Whether matte, glossy, stone-look, or concrete-look finishes, porcelain provides a rich surface identity that complements architectural design.

Unlike ceramics, which may fade or deteriorate over time, porcelain ensures long-term visual integrity—preserving the consistency and beauty of the space. In aesthetic pool tiles, surface properties that remain unchanged over time should be a decisive factor.

Choosing the Right Material by Application Area

While interior applications prioritize aesthetics, outdoor areas demand technical resilience. Ceramic may be suitable for semi-wet indoor areas like bathrooms or kitchens, but for pool surrounds, garden paths, spa areas, and facades, porcelain’s high-performance structure is essential.

These environments face not only water but also temperature changes, chemical cleaning agents, and physical impacts. That’s why the ideal pool cladding must go beyond looks and offer environmental durability.

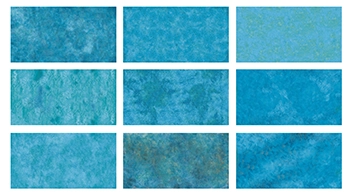

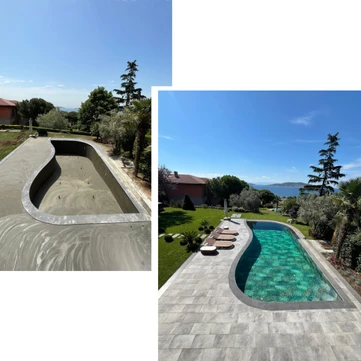

The Serapool Advantage: Long-Lasting Solutions with 100% Porcelain

Serapool distinguishes itself by offering not only visual refinement but also engineering superiority through its 100% porcelain tiles. Meticulously crafted tiles do not freeze, crack, or fade—retaining their elegance even after years of use.

Produced to international quality standards, Serapool’s porcelain tiles combine high-end technology with premium craftsmanship to ensure long-lasting performance for both private and public projects. Choosing Serapool means investing in durability, elegance, and sustainability all at once.

Moreover, porcelain is the most hygienic pool material, reducing maintenance needs while protecting user health. With Serapool’s 100% porcelain solutions, it’s possible to achieve a pool cladding that is not only elegant and safe but also built to last.