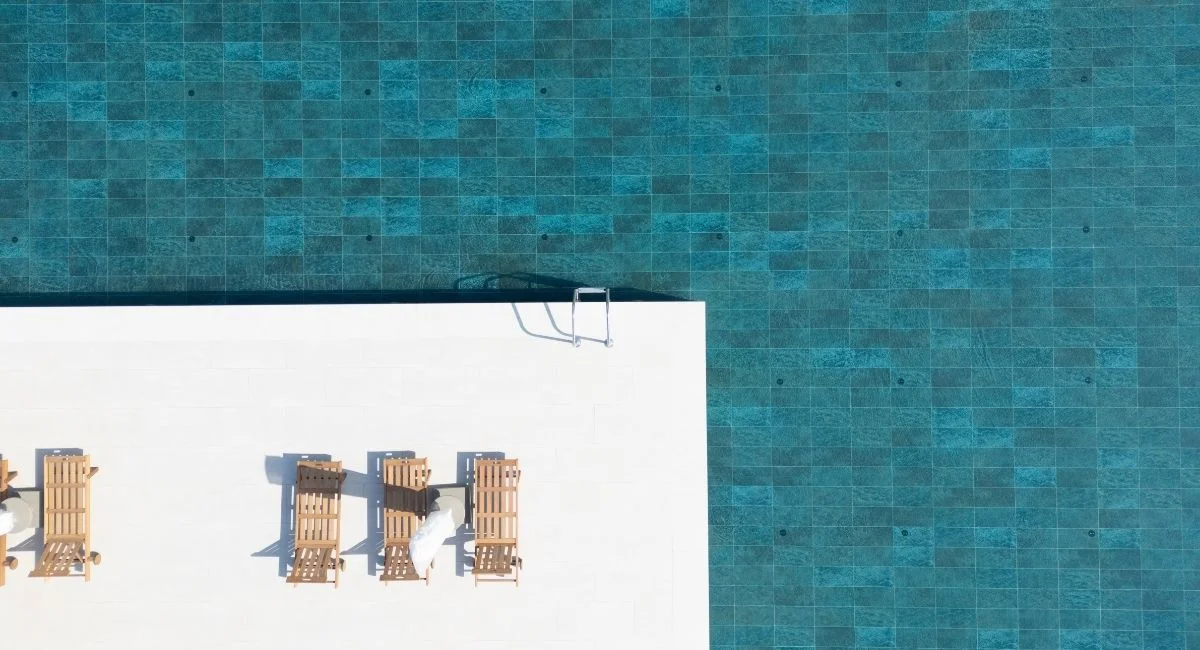

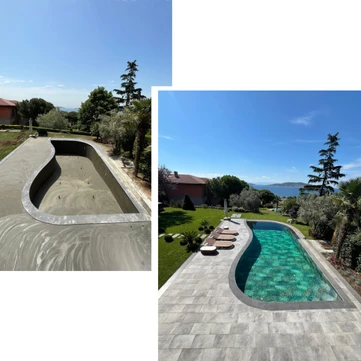

In pool projects, aesthetic integrity and technical compatibility are directly linked to the choice of tile dimensions. While the commonly used 30x60 cm tiles in the industry may limit design flexibility, Serapool Porselen stands out by offering an exclusive 33x66 cm size, providing innovative solutions beyond the standard.

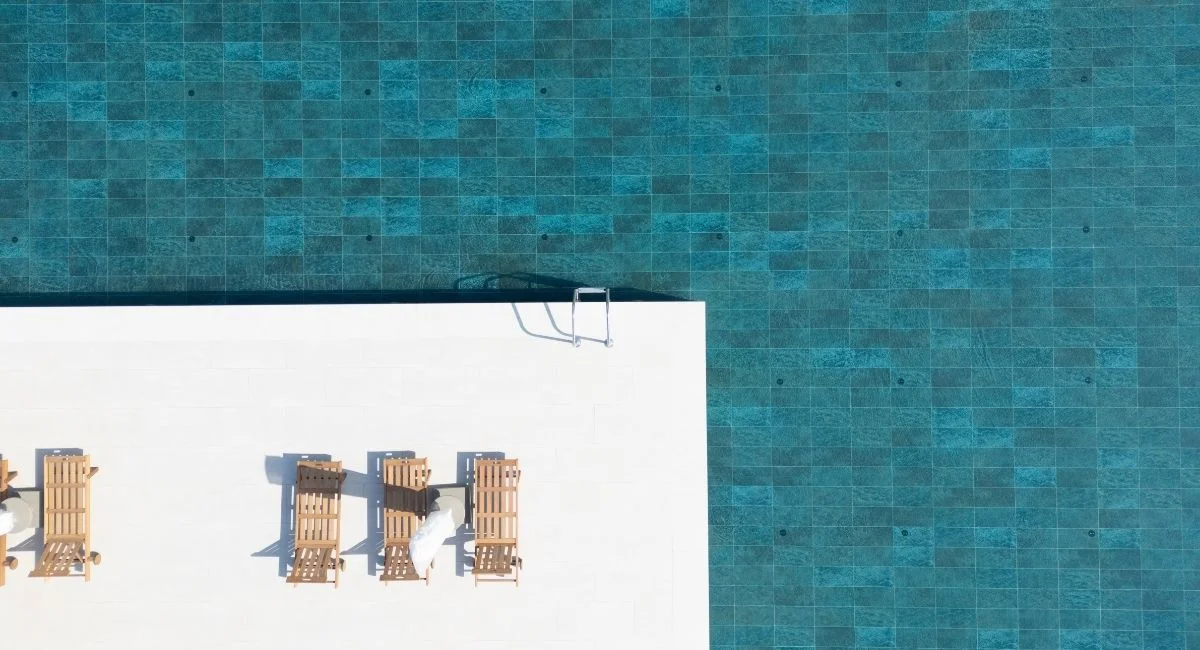

The 33x66 cm format allows professionals seeking distinction in pool design to achieve broader surface continuity and visual flow. With fewer grout lines during installation, these larger tiles offer a cleaner and more sophisticated appearance. This results in a refined design language for projects aiming for originality.

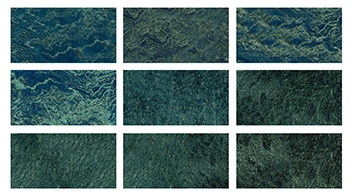

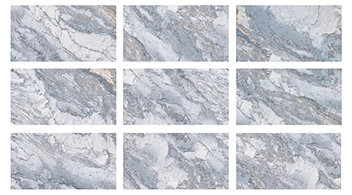

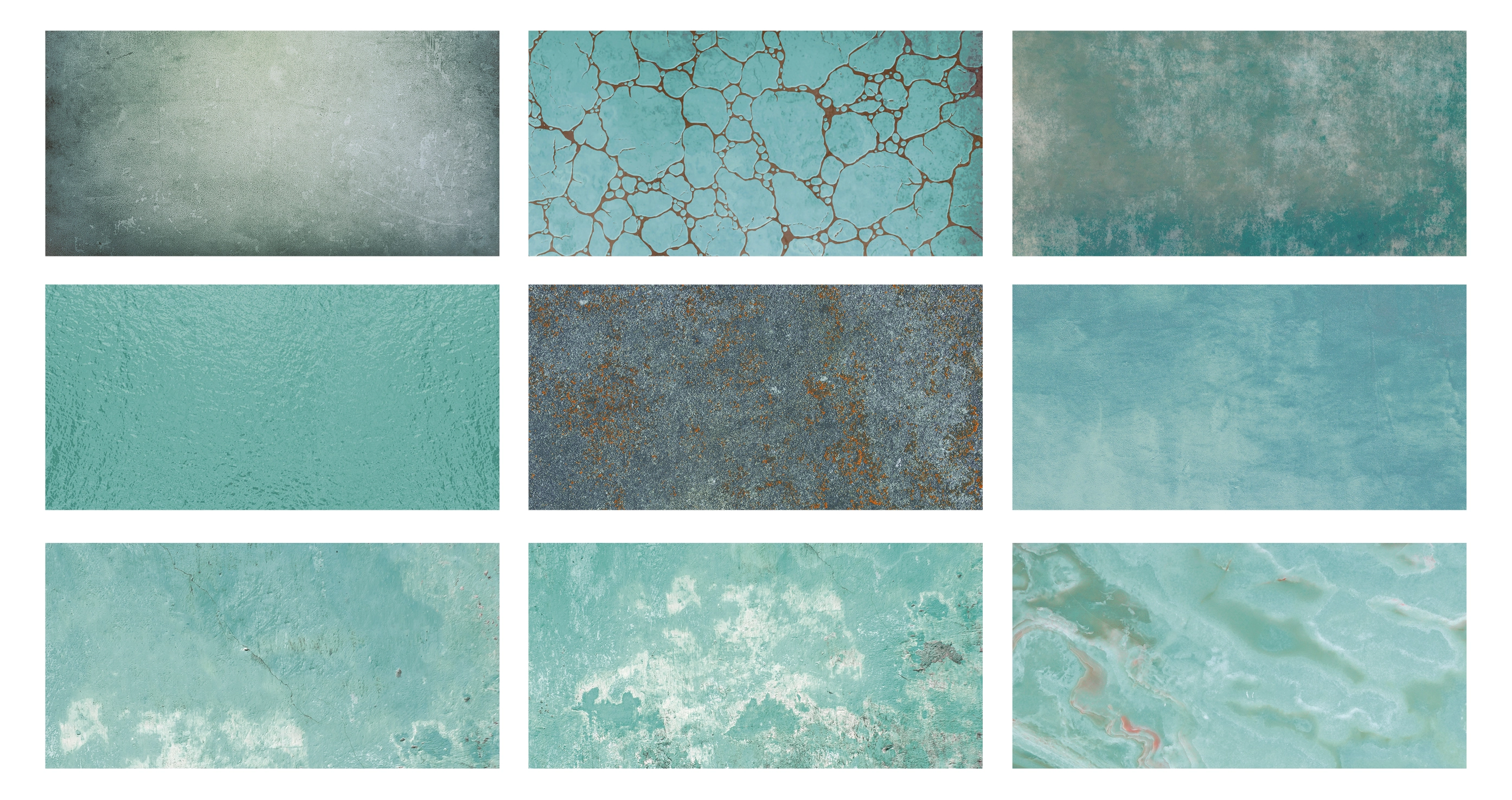

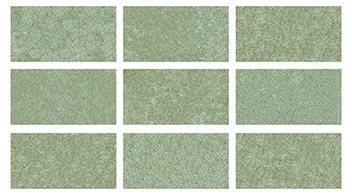

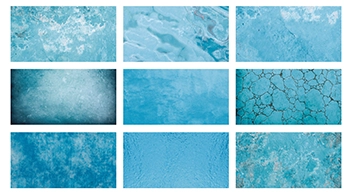

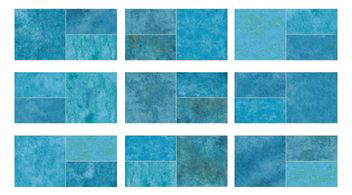

The Impact of 9 Face Variation in the Natural Series

Modern lifestyles increasingly favor a return to nature, influencing design trends as well. Created in response to this demand, Serapool’s Natural Series is inspired by natural elements. Featuring the “9 Face” variation, each tile presents a unique texture and tone, capturing the randomness of real stone surfaces. This diversity prevents repetition and adds a natural, organic touch to every space.

The Importance of Aesthetic and Architectural Harmony in Product Selection

Choosing from the Natural Series begins with aligning the tile selection with the pool’s function and architectural surroundings. While light colors evoke a sense of spaciousness, darker shades enhance depth. These choices should consider not only personal taste but also environmental harmony. A holistic assessment—from architecture to landscape—ensures aesthetic continuity. Professional consultancy and reference projects can provide valuable guidance in this process.

Top Picks: Five Stars of the Natural Series

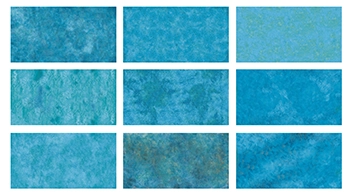

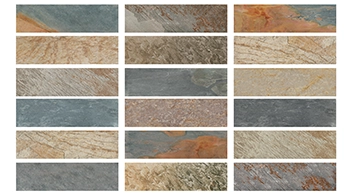

Among the most preferred options in the Natural Series are Olcay Mix, Firuze Mix, Verde Guatemala, Antique Grey, and Blue Bead. Each offers unique design potential:

- Olcay Mix: Timeless elegance with seamless color transitions.

- Firuze Mix: Vibrant tones that energize the space.

- Verde Guatemala: Brings the soothing essence of green into living spaces.

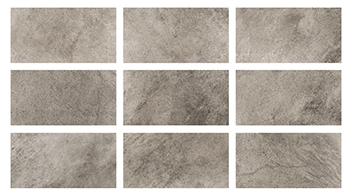

- Antique Grey: The embodiment of neutral sophistication.

- Blue Bead: Evokes serenity and calmness underwater.

Color Permanence and Long-Lasting Durability

Serapool products are fired at 1220°C, ensuring exceptional resistance to water, sunlight, and external elements. Their UV Resistance prevents fading or surface dullness, preserving their original appearance over time. This robust structure guarantees long-term performance and enduring aesthetics.

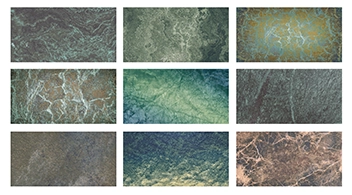

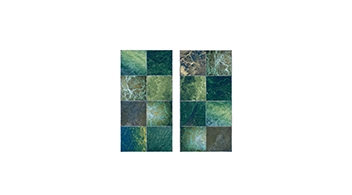

The Role of Dark Tones in the Natural Series

Developed with inspiration from nature, Serapool’s Natural Series goes beyond light tones. Darker hues reflect the depth of natural elements—earthy browns, lava black, and coral red create dramatic aesthetics underwater. This approach adds a new dimension to pool designs, transcending conventional looks.

Installation Guide: Technical Recommendations for a Natural Look

During installation, adjacent tiles with the same texture (face) should be avoided to prevent pattern repetition and enhance the natural stone effect. Using 3 mm wedge spacers, a combination of staggered joints and tile-cutting techniques helps achieve an organic layout.

Grout and Adhesive Selection: Crucial for Durability

Opting for light grey grouts conceals surface impurities and ensures a clean look. All adhesives and grouts must be suitable for outdoor conditions and compatible with porcelain tiles. Proper drying time and the use of rubber trowels ensure a clean finish without leaving marks.

Grout Widths: Balancing Aesthetics and Technical Requirements

Grout spacing varies by tile type. While a 5 mm joint is recommended for large-format products like the Olympic Series, a 3 mm joint is ideal for mosaics and the Natural Series. These measurements support both aesthetic continuity and material expansion.

Why Is Less Than 3 mm Grout a Risk?

Grout joints smaller than 3 mm cannot absorb the stress caused by water pressure and concrete movement, which can lead to cracking or surface damage over time. A minimum 3 mm gap ensures movement accommodation and long-term durability.

Why Is Grout Space Considered in Square Meter Calculation?

According to TS EN 14411 standards, both the nominal tile size and grout spacing must be considered in area calculations. This prevents aesthetic and technical issues during application and enables accurate square meter planning.